Discover the allure of the Birmingham Mint, renowned as one of the most iconic and storied mints in the world.

Discover the fascinating history of this Mint, including the challenges they overcame during times of war and much more in this informative article.

Experience the excitement now! Get ready to jump in headfirst!

The History of Birmingham Mint

In 1794, the visionary Ralph Heaton founded the Birmingham Mint as a brass foundry. Discover a subsidiary of the British Royal Mint, nestled in the heart of Birmingham, England.

The exceptional craftsmanship of The Mint, where they produce coins for circulation and bullion products for investors.

The diverse range of coins produced until 2003 featured an array of denominations, such as the classic bronze penny, the sleek copper 1p piece, and the luxurious gold sovereign.

How and When Did the Birmingham Mint Start

The rich legacy of the Birmingham Mint dates back to 1794. It all began with the visionary Ralph Heaton, a brilliant engineer and entrepreneur who founded his brass foundry.

In 1817, The Mint embarked on its journey to produce coins by acquiring equipment from the now-defunct Soho Mint.

Throughout its operation, the Mint has secured prestigious contracts to produce and mint various national currencies expertly.

18th Century

The rich legacy of the Birmingham Mint dates back to 1794. It all began with the visionary entrepreneur Ralph Heaton, who founded his brass foundry on historic Slaney Street in Birmingham.

Amid the Industrial Revolution, Heaton had already established himself as a skilled inventor, specializing in producing rose engines and tools utilized in the diverse trades of Birmingham, including metalworking.

As time passed, Heaton’s offspring followed in their father’s footsteps and became an integral part of the family enterprise.

In 1817, Ralph Heaton II, the fourth son of Heaton, laid the foundation of a new company within the premises of his father’s business.

At that time, the business had already shifted to neighboring Shadwell Street. Heaton II, following in his father’s footsteps, dedicated his efforts to crafting top-quality brass fittings in the foundry of metals.

But his expertise didn’t stop there. As a skilled former apprentice die-maker, Heaton II also lent his talents to producing dies.

In 1847, Heaton II’s enterprise transformed and was rebranded as Ralph Heaton and Son, following the addition of Ralph III to the family business.

In 1853, Heaton and Sons were born when George, the other son of the founder, joined the business. The moniker remained unchanged until the year 1889.

In October 1852, a novel prospect was presented to the Mint that went beyond the mere provision of coinage.

France is currently undergoing a significant re-coining initiative. They have contacted the Mint for assistance in managing and upgrading one of their minting facilities in the beautiful city of Marseille.

With a keen eye for detail, Heaton II personally supervised the project by relocating to Marseille with a select team of workers. While ensuring every aspect of the endeavor was executed to his exacting standards, he made occasional trips back to England. ‘

As Heaton II arrived at the French Mint, he was met with a disheartening sight. The once-great establishment was now in disrepair, with broken coin presses and rusting milling machines.

Without hesitation, he made the difficult decision to sell these remnants for scrap. New and improved machinery was promptly ordered from the prestigious Paris Mint, while state-of-the-art equipment was imported to Birmingham.

After completing the refurbishment, Heaton II invested a total of £3,700. With an impressive production of over 101 million coins, including 1, 2, 5, and centime pieces, the Marseille Mint has completed its five-year-long involvement in France’s recoinage.

19th Century

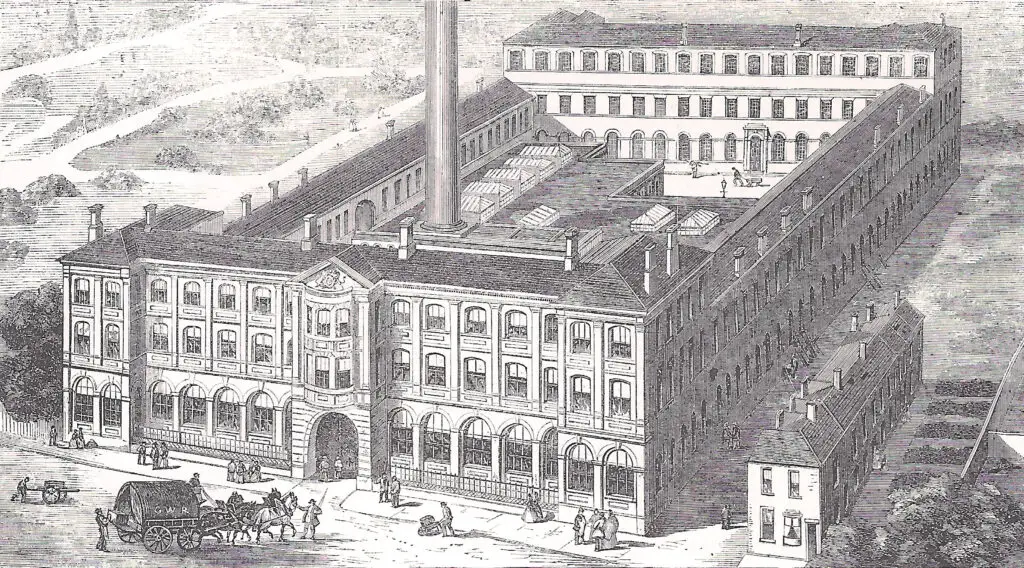

Upon Heaton II’s death in 1862, responsibility for the company fell to his eldest son, Ralph Heaton III, who had worked alongside his father for over twenty years and was already well-versed in coin making.

Around this time, the mint began a phase-out of its cumbersome, noisy screw press in favor of more modern lever presses, which could produce better quality strikes at a greater speed.

These lever-operated presses used at the mint were developed within the mint’s workshops and led to opportunities to supply foreign countries with minting equipment.

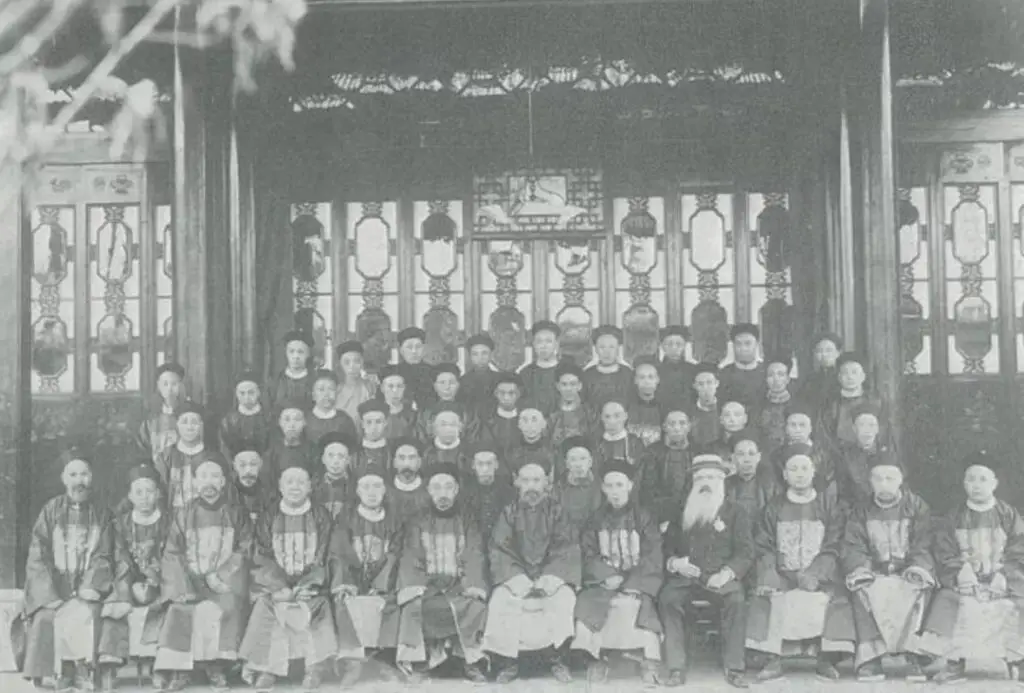

In 1887, the Birmingham Mint received a request from the Chinese government to assist in building and operating a state-of-the-art minting facility in Canton province.

Despite Empress Dowager Cixi’s efforts to introduce new machining techniques into China, previous attempts had failed. The mints in Zhili and Nanjing could not replace the well-established local cast cash coins.

While other regions remained largely untouched, Canton experienced a surge of Western influence as foreign merchants flocked to the area to trade in silver.

The grandeur of the Canton Mint, established in 1889, boasts 90 top-of-the-line lever coining presses imported from Birmingham. The mint’s production power is capable of producing a staggering 2.7 million coins per day – making it the largest mint in the world.

The Birmingham Mint Operative Department’s chief, Edward Wyon, stayed in China for a few years to supervise daily operations and train Chinese workers before returning to England.

20th Century

In 1923, the Royal Mint of the U.K. made a strategic decision to reassess the commercial potential of its operations.

With only a few exceptions for amicable nations, the Royal Mint has upheld a policy of refraining from minting coins for foreign powers, given its status as a governmental entity.

To preserve the integrity of the Birmingham Mint, the Royal Mint has generously agreed to allocate one-third of its overseas contracts.

Despite its impressive legacy, the Birmingham Mint faced a challenging new reality: it had to vie for new contracts and fight to maintain its foothold in the industry.

The impact of this decision on the future of the Birmingham Mint was monumental, signaling the beginning of a slow but steady decline for the establishment.

In 1991, the Birmingham Mint was acquired by the esteemed engineering firm IMI plc, which also held ownership of the IMI Mint in Witton, previously recognized as the King’s Norton Mint.

The efficiency of their restructuring plans as they merge operations and close the Witton minting facility.

The Hockley plant on Icknield Street is now the hub of its streamlined operations. Introducing the newly amalgamated mint, formerly known as the IMI Birmingham Mint.

However, it underwent a name change and was ultimately rebranded as The Birmingham Mint after its acquisition by venture capital firm 3i for a whopping £18 million in 2000.

In the early 2000s, a financial setback arose due to a disagreement with the Royal Mint concerning the historic entitlements to profits on overseas contracts.

Since the 1960s, the Birmingham Mint has allegedly had an unwritten agreement with the Royal Mint to receive one-third of all orders outside Europe. In a contentious turn of events, The Royal Mint challenged this assertion.

Consequently, on the 12th of June in 2002, the Birmingham Mint initiated legal proceedings in the High Court, seeking £5.4 million in damages from the Treasury.

Discover how former chief executive Roland Vernon acquired the mint from owner 3i two years before the court case. Vernon boldly submitted a memorandum to Parliament advocating for private companies to be granted the rights to mint British coins through a tender process.

He cited the Royal Mint’s lackluster financial performance as evidence to support his proposal.

In 2001, the Royal Mint managed to record an impressive operating profit of £5.2 million, surpassing their previous record loss of £6.5 million.

However, despite this achievement, the mint suffered a significant loss in business from overseas contracts.

As a result, in 2003, the mint was compelled to enter administration under the guidance of KPMG. Experience the seamless transition of ownership as JFT Law & Co., Ltd. takes over the company’s reins.

The assets of the business have been entrusted to the capable hands of liquidators Stirchley Machine Tools, Ltd.,

Thanks to the Birmingham City Council’s support. The mint was transformed into a museum in 2003.

Later in 2011, the remaining part of the mint was moved to Kidderminster, located just outside Birmingham.

Before you go…

We hope you have enjoyed reading about Birmingham Mint’s history and coin production’s evolution. We know there are many other fascinating stories to tell about this industry, so please let us know what you think in the comments below!

Check out my next article: “Pobjoy Mint – An Introduction.“

Related Articles:

Thank you but I cannot find any mention of a Silver coin my father purchased to

remember the visitof Queen Elizabeth II to the USA for its Bicentenary .It was minted in July 1976